One platform.

Total control for all PCBA Inspection Stages.

Adaptable across production phases, from Automated Optical Inspection to Solder Paste Inspection, Delvitech empowers engineers with a single, smart inspection program. Flexible, consistent, and ready for every production phase.

Discover more

Eyes you can trust.

Performance you can measure.

AOI and SPI inspection machines designed for precision, scalability and speed.

Across every SMT and THT production phase, Delvitech designs and builds cutting-edge AOI and SPI systems that combine AI-native intelligence with world-class engineering. The result? Faster, more stable processes, drastically reduced false calls, minimal material waste, and lower CO₂ emissions, improving your production and sustainability.

AOI_NEURAL_SYS

3D AOI for

all types of boards

AOI_SPI_NEURAL_SYS

AOI and SPI

fast inspection

≤ 6

CAMERA

4 CONF.

ELEMENTS

≤ 5 KG

PCBs

≤ 6

CAMERA

Z

AXIS

80 MM

RANGE

What powers

your performance.

NEITH Software

Web-based AI-powered platform that boosts production output, prevents defects, and increases the first-pass yield.

Training Manager

On-machine training that learns without forgetting, continuously improving without halting production.

Self-programming

Coming soon: reduce setup time with automatic component recognition, package matching, and parameters optimization.

See how it

all connects.

Scroll horizontally

Horus

3D AOI + SPI for PCB Inspection

Patented optical heads + AI brain

A scalable, upgradable platform

Instant Insight, Zero Bottlenecks

Ready for Any Board

Aton

The 3D AOI solution for all types of boards

Z-Axis movement

Clearance for every project

Real 3D acquisition

Swiss precision thinking.

Powered by AI. Perfected by Design.

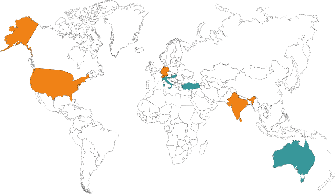

All research, development, prototyping and production activities are carried out within Switzerland. Plus, we collaborate with two dynamic Swiss institutions dedicated to the advancement of Artificial Intelligence and technology: The Dalle Molle Institute for Artificial Intelligence and The Department of Innovative Technologies at SUPSI.

More reliable

detections.

Higher material

efficiency. Every time.

Sustainability starts with precision

By reducing false positives, rework, and scrap, Horus optimizes every step of your production, minimizing material waste and energy use. Fewer errors mean fewer resources consumed and less CO₂ emitted. A smarter path to a responsible, cost-efficient manufacturing.

A SEF.Growth Labeled Company

The SEF.Growth High-Potential Label, granted by the Swiss Economic Forum (SEF), recognizes companies with demonstrated growth potential and a strong strategic vision. In 2025, Delvitech proudly received this prestigious award.

Environmental Responsibility

Our commitment to social responsibility begins with our choice of materials, our effort to combat plastic waste, and our dedication to environmental and societal well-being.

More reliable

detections.

About us

Moving towards the future.

Together.

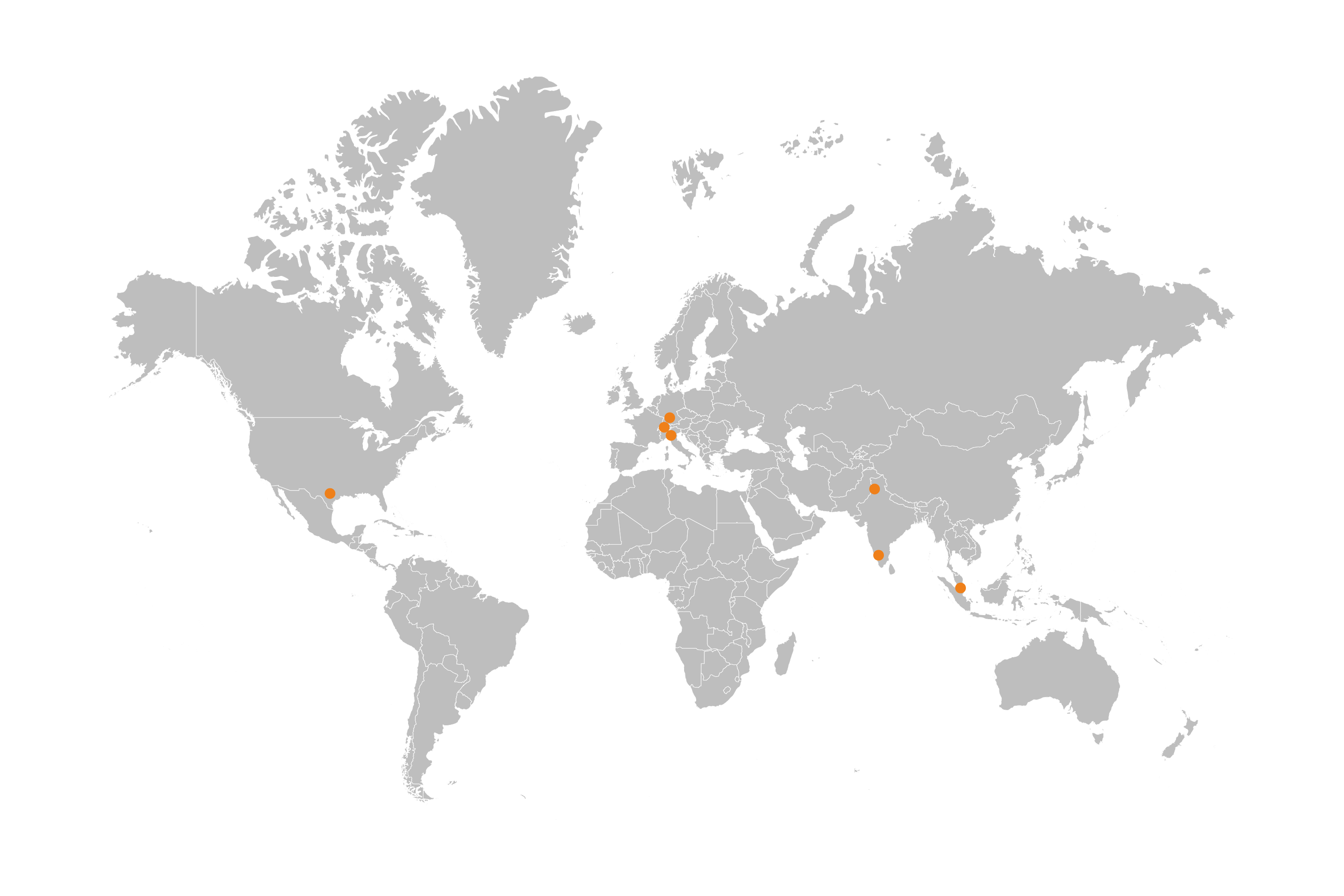

Delvitech Worldwide

-

Switzerland

Delvitech SA

-

India

DelvitechAI Vision Systems India Pvt. Ltd.

-

United States

Delvitech Inc

-

Germany

Delvitech GmbH

-

Singapore

Delvitech

-

Italy

Delvitech srl

Get In Touch

Swiss by design. Intelligent by nature.

Our mission is to revolutionize the optical inspection industry through an innovative, adaptable, and eco-friendly solution that enhances efficiency and cost-effectiveness while minimizing raw material waste and CO2 emissions.

Discover Delvitech