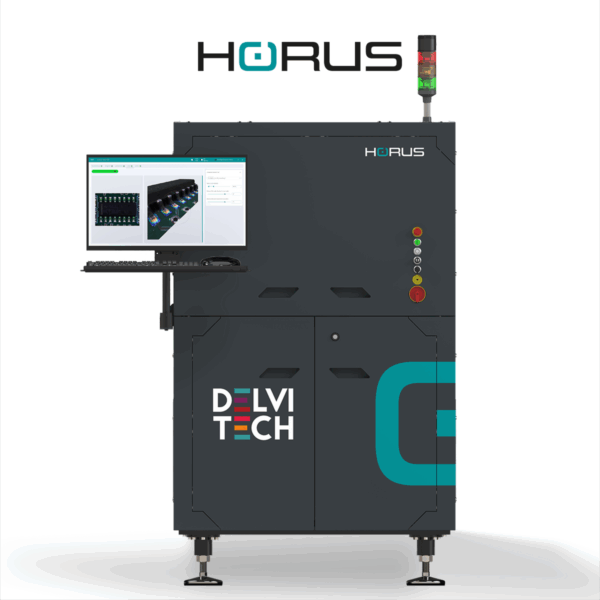

In today’s fast-paced electronics manufacturing landscape, the pressure to deliver perfect products — faster and more efficiently — is greater than ever. As industries raise the bar for quality standards, Automated Optical Inspection (AOI) systems are stepping into a new era. And among the names driving this evolution, Delvitech is steadily carving out its place as one of the most innovative and reliable AI-powered AOI providers.

What makes Delvitech worth paying attention to?

It’s not just about checking boxes on performance specs. Delvitech is doing something deeper — reimagining AOI through the lens of artificial intelligence, automation, and adaptability. It’s offering manufacturers a smarter, more resilient way to inspect, learn, and improve.

AI That Actually Learns from the Line

Many AOI solutions claim to use AI. In practice, though, they often rely on static rule sets or generic image databases. Delvitech takes a fundamentally different approach: its systems learn from your production environment.

At the core of Delvitech’s solution is a powerful, proprietary AI engine trained using deep neural networks, developed and fine-tuned through a dedicated model training and validation platform. This setup isn’t just an add-on; it’s part of a fully integrated ecosystem designed to continuously refine defect detection accuracy over time — directly from real-world data.

This means that with every inspection, the system gets better. It adapts to new board designs, evolving component shapes, and even subtle lighting variations — with minimal operator intervention. That’s not just automation. That’s adaptive intelligence.

Seeing More, Catching More: True 3D Vision

Another area where Delvitech truly shines is its imaging technology. By combining high-resolution 3D scanning with multi-domain analysis, the system can detect a wide range of defects with remarkable precision — from classic soldering issues to more nuanced shape deformations or alignment shifts.

Instead of relying solely on 2D visual cues, Delvitech’s system captures and interprets depth, height, volume, and surface geometry, providing a more complete picture of each component and solder joint.

The result? Fewer false calls, fewer escapes, and a dramatic boost in first-pass yield.

Built for the Smart Factory — Not Just Today’s, But Tomorrow’s

Delvitech isn’t just designing for the AOI needs of today — it’s preparing customers for the future. Its architecture is natively aligned with Industry 4.0 standards, offering seamless integration into smart manufacturing systems. Whether you’re operating a single line or coordinating production across multiple sites, Delvitech offers the scalability and connectivity needed to centralize control and synchronize quality data.

Advanced features such as cloud-enabled model deployment, remote diagnostics, and SPC dashboards put real-time insights directly in the hands of operators, engineers, and decision-makers — wherever they are.

Human-Centered by Design

While Delvitech’s technology is cutting-edge, its interface is refreshingly human. The system has been carefully designed with usability in mind, making it easy for operators to set up inspections, validate results, and even contribute to AI training workflows.

By simplifying complex tasks through intuitive tools and guided processes, Delvitech empowers teams to do more — with less time, less training, and fewer errors.

A Proven Partner in High-Stakes Sectors

Delvitech’s solutions are already trusted by manufacturers in some of the most demanding sectors — including automotive, aerospace, medical electronics, and telecom. These are industries where a single undetected defect can mean a costly recall or a safety-critical failure. In such environments, reliability, accuracy, and traceability aren’t just nice-to-haves. They’re non-negotiable.

And Delvitech delivers — with tools that not only detect problems but will soon help prevent them, supporting predictive quality and process optimization in real time.

A Proven Partner in High-Stakes Sectors

Delvitech’s solutions are already trusted by manufacturers in some of the most demanding sectors — including automotive, aerospace, medical electronics, and telecom. These are industries where a single undetected defect can mean a costly recall or a safety-critical failure. In such environments, reliability, accuracy, and traceability aren’t just nice-to-haves. They’re non-negotiable.

And Delvitech delivers — with tools that not only detect problems but will soon help prevent them, supporting predictive quality and process optimization in real time.

Why Delvitech Belongs on Every AOI Shortlist

If you’re evaluating AOI systems — especially those claiming to harness artificial intelligence — Delvitech deserves your full attention. It brings together:

- A mature, fully integrated AI training and inspection platform

- State-of-the-art 2D/3D vision systems

- Exceptionally low false call and escape rates

- A future-ready architecture that scales with your production needs

In short, Delvitech offers not just an inspection system — but an intelligent quality ecosystem that evolves with your products and your processes.

So when the conversation turns to the best AI-powered AOI systems, it’s not just a matter of who’s using AI — but how intelligently it’s being used.

And that’s where Delvitech leads.