The AOI + SPI solution for industries requiring fast inspection

Horus is a revolutionary hybrid 3D inspection solution driven by Artificial Intelligence, capable of conducting both Automatic Optical Inspection and Solder Paste Inspection. By redefining norms and expectations, it seamlessly integrates into all facets of SMT production, revolutionizing the inspection processes. Horus, characterized by the possibility of a dual lane conveyor with fast loading and unloading, a moving optical head and the ability to inspect mechanical components, is the perfect solution for those industries requiring fast inspection.

Hardware

- Patented true 3D measurement optical technology

- Moving optical head with linear motors

- Top clearance up to 55 mm

- Bottom clearance up to 55 mm

- Boards up to 5 Kg and 560×550 mm

- Loading and unloading in less than 2 seconds

Specifications expressed herein may be subject to change.

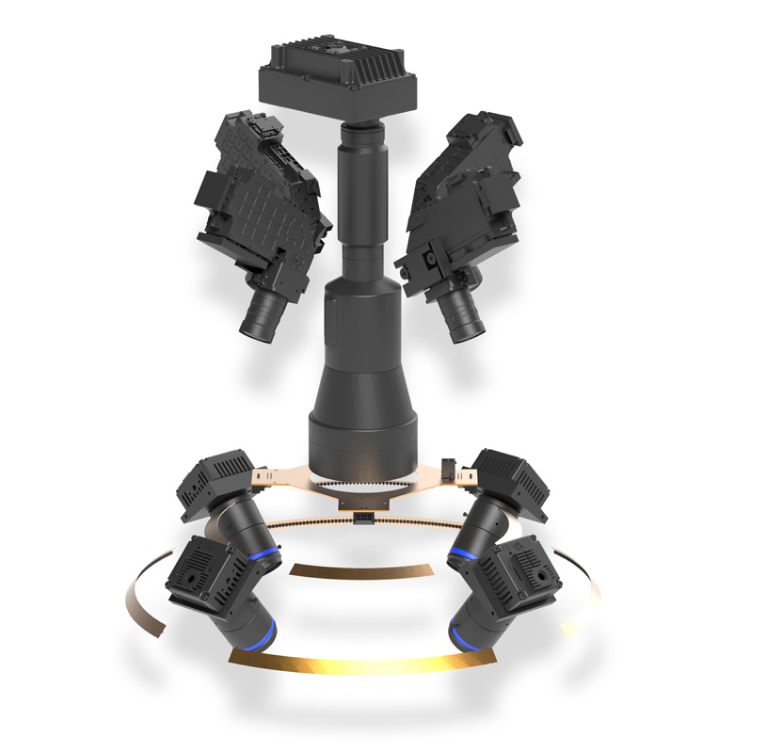

Optical Head Technology

- Up to 6 intelligent cameras

- High-resolution, high-speed top camera with FPGA integrated

- Polarized camera for enhanced inspection capabilities (optional)

- 4 side cameras (optional)

- 4 digital projectors for true 3D reconstruction

- 3 levels RGBW LEDs

Specifications expressed herein may be subject to change.