The only truly AI-based solution

Neural networks have transformed inspection systems, revolutionizing image processing through their ability to identify and manage a wide range of variables.

Unlike traditional AOI systems, which rely on parameter- and threshold-based methods and often struggle to adapt to the many variations that arise during production, Delvitech’s advanced technology based on proprietary neural networks is specifically designed to overcome these limitations, delivering a host of significant benefits.

Minimal manual configuration

Our technology minimizes the need for human intervention by independently identifying and defining PCB components with exceptional accuracy

Tailored inspections

With neural network training, Delvitech delivers fully customized inspection processes, designed to meet the specific requirements of each customer

Reduced false positives

By cutting false positive rates by a factor of 10 compared to industry competitors, our machines ensure greater reliability and consistency

Unmatched accuracy

Whether you are working with diverse PCB types or navigating complex production stages, Delvitech guarantees precision and efficiency at every step

Training Manager

Our solution allows training to happen directly on the machine, activating a process of continuous inspection improvement, resulting in increased production efficiency

A continuously evolving technology

Delvitech’s AI technology paves the way for future advancements. Our solution will in fact have the capability to detect errors before they occur by identifying process deviations within the production sequence. Future features will also include self-programming capabilities, to automatically recognize components and make real-time adjustments during production.

A custom, patented hardware

Delvitech custom, patented hardware is designed specifically to gather the precise data required to train highly specialized proprietary neural networks.

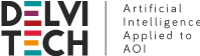

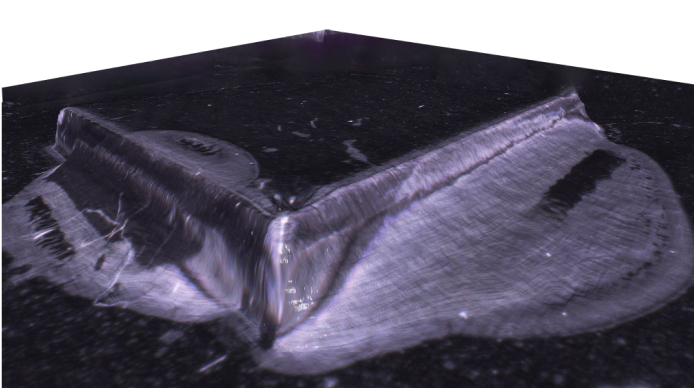

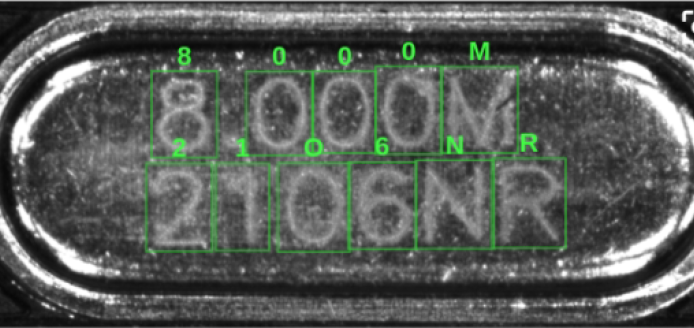

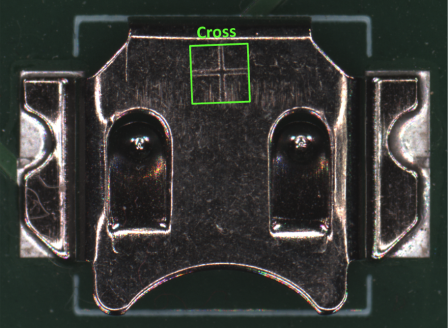

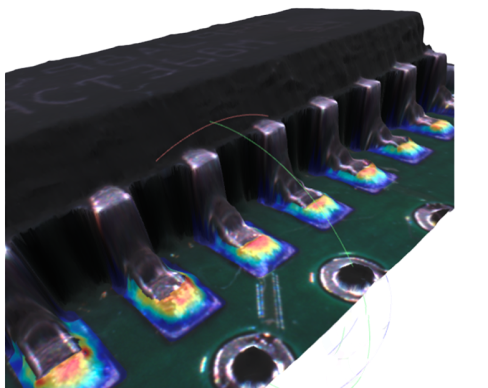

At the core of this innovation is the patented optical head, a cutting-edge technology that captures accurate 3D data and delivers crystal-clear images across a diverse range of packages and components. Whether dealing with tall connectors featuring reflective metallic surfaces, fine-pitch components or transparent glues, the system ensures unparalleled precision and adaptability.

Transparent glue 3D reconstruction

OCR

Screws 3D reconstruction

Pin detection

Polarity

Solder joint

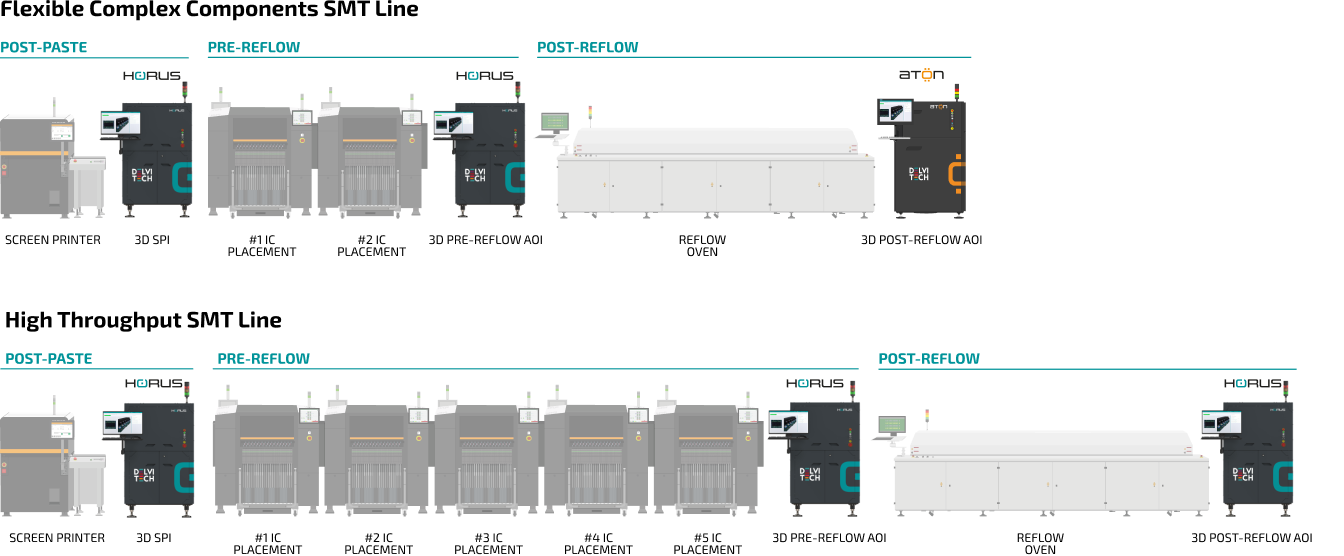

One single solution for all PCBa Inspection Stages

Delvitech equips line engineers with a single, flexible inspection program designed to streamline operations and maintain consistency. Seamlessly adaptable across production phases—be it AOI or SPI—this solution ensures efficiency at every step. With cloud integration, the program can be effortlessly shared across multiple manufacturing facilities, enabling uniform results and minimizing programming efforts, regardless of production location.

Solutions for the entire electronics industry

From Microelectronics to Chiplets

With the seamless integration of advanced hardware and AI-powered software, our versatile technology adapts to any type of inspection. Since Q4 2021, when our Automated Optical Inspection (AOI) system was launched, Delvitech has been pioneering the PCB assembly industry. In Q4 2024, we introduced a hybrid solution combining AOI and SPI, further enhancing our capabilities. Looking ahead, the first prototype of our microelectronics inspection machine is expected in 2026, and a cutting-edge chiplet inspection solution is planned for release in 2027. Delvitech continues to deliver reliable defect detection without compromising efficiency, now preparing to lead in the rapidly evolving fields of microelectronics and chiplet inspection.